In industrial and commercial settings, the proper storage of gas cylinders is not just a matter of organization—it’s a critical safety requirement. Different types of gas cylinders contain substances that can pose significant hazards if not properly secured and stored. A high-quality tank cage provides essential protection against falls, impacts, and unauthorized access, while ensuring compliance with safety regulations.

Understanding Gas Cylinder Risks

Gas cylinders contain pressurized contents that can be flammable, oxidizing, toxic, or corrosive. The potential dangers associated with improper gas storage include:

- Physical hazards from unsecured cylinders falling over

- Valve damage leading to uncontrolled gas release

- Fire or explosion risks with flammable gases

- Chemical exposure from leaking cylinders

- Regulatory non-compliance resulting in fines or penalties

When these cylinders are not secured in a proper gas cage, they become vulnerable to accidents that could lead to catastrophic outcomes. According to industry safety standards, securing cylinders upright and protected is a fundamental requirement in any workplace handling industrial gases.

Flammable Gases: Essential Tank Cage Requirements

Flammable gases such as propane, acetylene, and hydrogen represent some of the highest-risk materials requiring secure storage solutions. These gases can ignite easily when exposed to heat sources or sparks, making a specialized tank cage absolutely essential.

For flammable gas storage, cages should feature:

- Ventilated design to prevent gas accumulation

- Separation from oxidizers and ignition sources

- Clear hazard labeling and access restrictions

- Weather protection while maintaining airflow

- Secure locking mechanisms to prevent unauthorized access

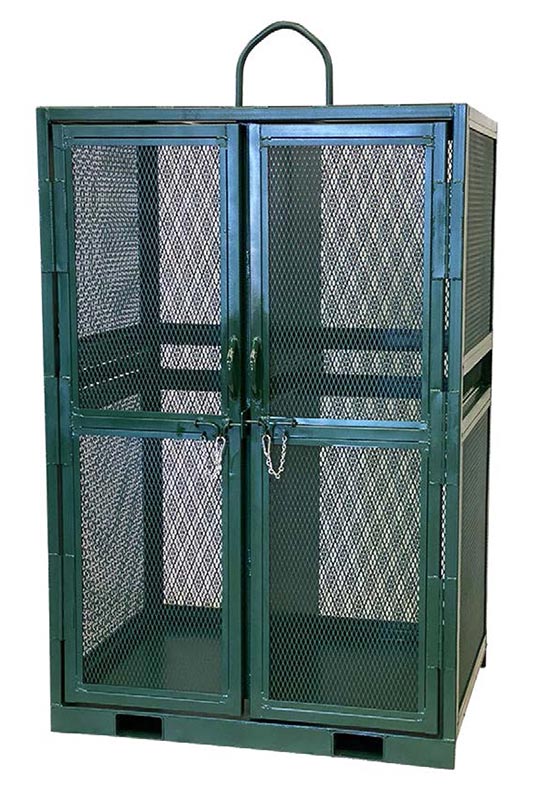

Anthony Carts manufactures industrial-grade cylinder cages specifically designed to meet these stringent requirements for flammable gas storage. Our cages are built with reinforced frameworks that exceed industry safety standards while providing convenient access for authorized personnel.

Toxic and Corrosive Gas Storage Solutions

Toxic gases like chlorine, ammonia, or hydrogen sulfide require specialized gas storage solutions that prioritize containment in case of leaks. Similarly, corrosive gases such as hydrogen chloride can damage equipment and pose serious health hazards if not properly secured.

When storing these hazardous materials, a properly designed gas cage provides an essential first line of defense. These cages should be constructed with corrosion-resistant materials and include features that allow for quick visual inspection of cylinder conditions without requiring handling.

The storage area should be clearly marked with appropriate hazard warnings and restricted to trained personnel only. Proper ventilation remains critical, particularly for gases that can cause respiratory damage even in small concentrations.

Oxidizing Gases and Compatible Storage

Oxygen and other oxidizing gases present unique storage challenges. These gases don’t burn themselves but vigorously accelerate combustion of other materials. When storing oxidizers, strict separation from flammable materials is mandatory.

Oxidizing gas cylinders must be kept in dedicated storage areas with specialized tank cages that maintain at least 20 feet of separation from combustible materials or protected by fire-resistant barriers. These cylinders should never be stored near oils, greases, or other hydrocarbon materials that could create fire hazards if exposed to high-oxygen environments.

Proper storing cylinders of this type requires regular inspection of the surrounding area to ensure no compatible materials have been introduced to the storage location.

Inert Gases: Safety Beyond Reactivity

While inert gases like nitrogen, argon, and helium don’t present combustion or reactivity hazards, they still require proper gas cage storage for physical safety and asphyxiation prevention. These gases can displace oxygen in confined spaces, creating dangerous conditions without warning signs like odor or irritation.

Secure storage of inert gas cylinders prevents accidental damage to valves that could lead to rapid gas release in enclosed spaces. Even though these gases aren’t flammable or toxic, their high-pressure nature still presents physical hazards that require proper securing mechanisms.

A quality tank cage provides the necessary stability to prevent these heavy cylinders from tipping over and potentially causing injury to personnel or damaging expensive equipment.

Weather Considerations for Outdoor Gas Storage

Outdoor storing cylinders introduces additional factors that must be addressed in gas storage planning. Exposure to elements can affect both the cylinders and their contents, potentially compromising safety.

Quality gas cages designed for outdoor use provide protection from:

- Direct sunlight which can increase cylinder pressure

- Rain and moisture that may cause corrosion

- Snow accumulation that could block access or ventilation

- Temperature extremes affecting gas properties

- Wind that might topple unsecured cylinders

Anthony Carts offers specialized outdoor tank cages constructed with galvanized or powder-coated steel that withstand harsh environmental conditions while maintaining security and accessibility for your gas cylinder inventory.

Regulatory Compliance for Cylinder Storage

Navigating the complex regulatory landscape governing gas storage is essential for any business using industrial gases. Organizations including OSHA, DOT, and local fire codes establish specific requirements for storing cylinders of different gas types.

These regulations typically mandate:

- Separation distances between incompatible materials

- Ventilation requirements for enclosed storage areas

- Maximum quantities allowed in specific locations

- Fire protection systems for high-hazard gases

- Security provisions to prevent unauthorized access

Non-compliance with these regulations can result in significant penalties, insurance complications, and increased liability exposure. Properly designed gas cages help ensure your facility remains compliant with applicable regulations while providing practical storage solutions.

Implementing Best Practices for Gas Cylinder Management

Beyond the physical gas cage infrastructure, implementing robust management procedures enhances safety and efficiency in handling gas cylinders. These practices include:

Regular inventory audits to track cylinder locations and conditions create accountability throughout your organization. Implementing clear protocols for cylinder handling during delivery, use, and transport reduces the risk of accidents and damage. Training staff on emergency response procedures specific to different gas types prepares them for potential leaks or other incidents.

Maintaining clear access paths to gas storage areas ensures that cylinders can be reached quickly in emergencies, while regular inspection of cage integrity prevents deterioration of your safety infrastructure over time.

Anthony Carts specializes in designing and manufacturing industrial gas storage solutions that address all these considerations. Our team can help you assess your specific needs and develop a customized tank cage system that optimizes both safety and operational efficiency. Contact us today to discuss how we can enhance your gas cylinder storage safety.